Understanding the Basics of n55 Catless Downpipe

What is an n55 Catless Downpipe?

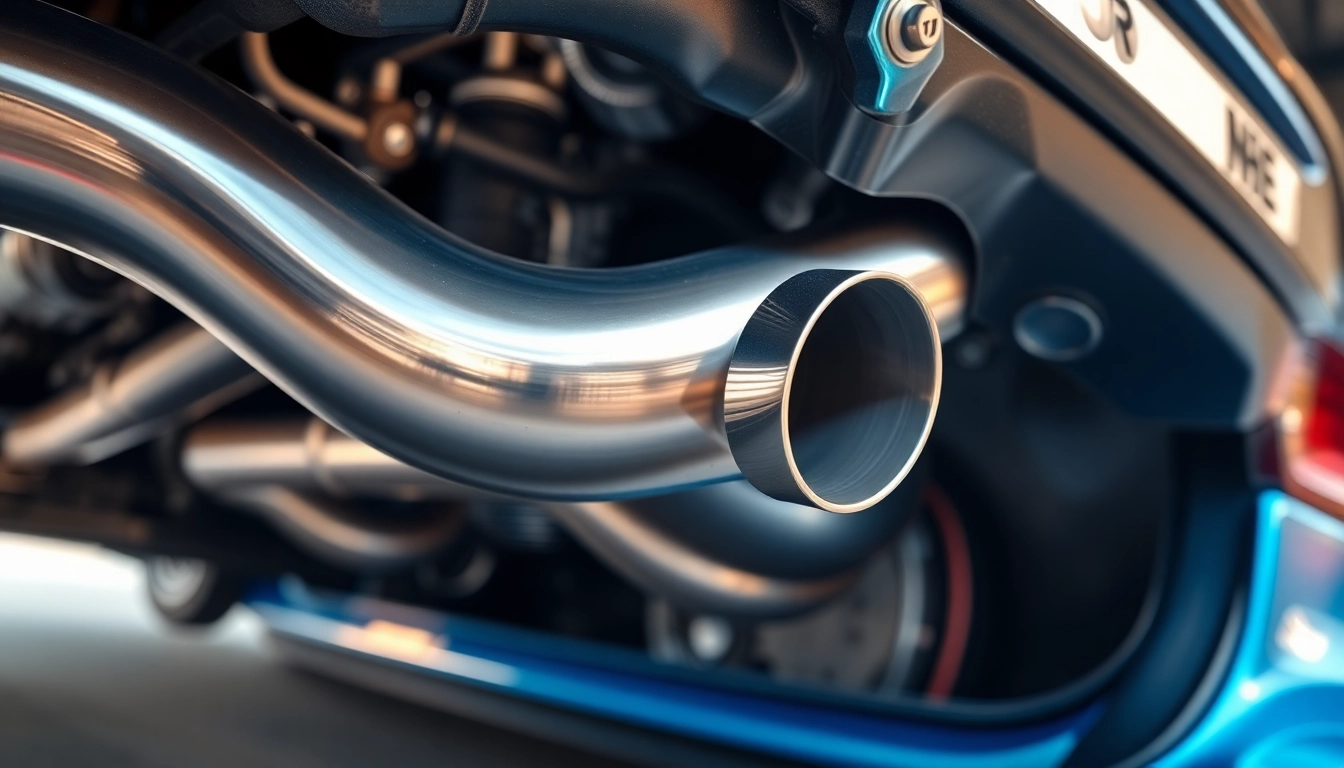

The n55 catless downpipe is an aftermarket component designed to replace the factory downpipe in BMW vehicles equipped with the N55 engine. This performance upgrade essentially eliminates the catalytic converter from the exhaust system, thereby enhancing the vehicle’s exhaust flow. The downpipe plays a critical role in directing exhaust gases away from the engine and toward the exhaust system, contributing to improved overall performance and efficiency.

Benefits of Catless Downpipe Installations

Installing an n55 catless downpipe offers several notable benefits, including:

- Improved Exhaust Flow: With no catalytic converter in place, exhaust gases can exit the engine more freely, reducing backpressure and enhancing performance.

- Increased Horsepower and Torque: A more efficient exhaust system translates directly into notable gains in horsepower and torque, allowing for a more responsive driving experience.

- Weight Reduction: Factory downpipes are often heavier due to the materials used for catalytic converters. Transitioning to a lightweight catless downpipe reduces the overall weight of the vehicle.

- Enhanced Sound: Removing catalytic converters typically results in a more aggressive exhaust note, appealing to many performance enthusiasts.

- Cost-Effective Performance Upgrade: Compared to other modifications, upgrading to an n55 catless downpipe is generally more affordable while providing substantial gains in power and performance.

Key Differences between Catless and Catted Options

Understanding the differences between catless and catted downpipes is crucial for anyone considering an upgrade.

- Catted Downpipe: Equipped with a catalytic converter, these downpipes comply with emissions standards and are typically quieter.

- Catless Downpipe: Designed without a catalytic converter, these options maximize exhaust flow and performance but are not street-legal in many regions due to emissions regulations.

The choice between the two largely depends on personal preferences, legal considerations in your area, and the desired performance level from your BMW N55 engine.

Performance Improvements from n55 Catless Downpipe

How It Affects Exhaust Flow

The n55 catless downpipe significantly enhances exhaust flow by removing potential restrictions that the catalytic converter can impose. The improved flow allows exhaust gases to exit the engine faster, preventing buildup and backpressure that can hinder engine performance.

This increased flow rate is critical in high-performance situations where maximizing the output of the engine is imperative. An efficient flow path increases the engine’s ability to expel exhaust gases and enhances the intake of fresh air, contributing to better combustion efficiency.

Impact on Engine Performance and Responsiveness

Replacing the factory downpipe with an n55 catless downpipe can lead to noticeable improvements in engine performance and responsiveness:

- Throttle Response: Drivers often report a more immediate throttle response as the engine can expel exhaust gases more quickly, allowing for quicker acceleration.

- Power Gains: On a dyno, vehicles with catless downpipes often showcase substantial horsepower and torque increases, especially when combined with other performance modifications such as tuning and enhanced air intake systems.

- Better Fuel Efficiency: Although catless downpipes primarily serve performance, they can also lead to improved fuel efficiency due to better exhaust flow and combustion efficiency.

Typical Performance Gains in Real-World Scenarios

Real-world scenarios highlight the performance gains that can be achieved with an n55 catless downpipe. Depending on the specific vehicle and accompanying modifications, drivers can expect an increase of:

- 15-30 horsepower

- 20-40 lb-ft of torque

- Improved 0-60 mph times by up to half a second in some cases.

These improvements depend on various factors such as the condition of the vehicle, additional modifications, and tuning adjustments post-installation.

Installation Process for n55 Catless Downpipe

Tools Required for Installation

For anyone considering an installation of the n55 catless downpipe, it’s essential to have the right tools at hand. Here’s a list of recommended tools for the installation process:

- Socket Set (including extensions)

- Torque Wrench

- Screwdrivers (flat and Phillips)

- Pipe Cutter or Sawzall

- Pliers

- Jack and Jack Stands

- Safety Gear (gloves and goggles)

Step-by-Step Installation Guide

While the installation process can vary depending on the specific BMW model and configuration, the following is a general step-by-step guide:

- Preparation: Ensure the vehicle is parked on a flat surface. Raise the vehicle using a jack and place jack stands for safety.

- Remove the Undertray: If equipped, remove any undertrays covering the exhaust system for easy access.

- Disconnect Exhaust Components: Unbolt and disconnect the exhaust from the turbocharger and any other connecting points. Be cautious of heat shields and flexible joints.

- Remove Factory Downpipe: Carefully extract the factory downpipe, noting its orientation for easier installation of the new unit.

- Install the Catless Downpipe: Position the n55 catless downpipe and ensure it aligns with turbo outlets and exhaust flanges.

- Reattach Components: Reconnect the exhaust and any necessary components, ensuring all bolts are tightened to the manufacturer’s recommended torque specification.

- Check for Leaks: Once installation is complete, start the vehicle and inspect for any exhaust leaks.

Common Challenges and Solutions During Installation

Installation of a catless downpipe may present challenges. Here are common issues and tips to overcome them:

- Rusty Bolts: In older vehicles, bolts can be rusted or seized. In such cases, use penetrating oil to loosen them before attempting removal.

- Limited Space: Certain modifications may be challenging in tight spaces. Consider using a universal joint socket extension to reach difficult angles more easily.

- Alignment Issues: Proper alignment is essential for a secure fit. Ensure that all mounting points line up correctly to avoid stress on exhaust components.

Legal Considerations and Emissions Regulations

Understanding Local Emissions Laws

Before installing an n55 catless downpipe, it’s crucial to understand the emissions laws in your locality. In many regions, modifications that render a vehicle non-compliant with emissions regulations can lead to fines or legal issues. Research your state’s or country’s specific rules regarding catalytic converters and emissions to ensure compliance.

How to Comply with Regulations When Using Catless Downpipes

For those who desire the performance benefits of an n55 catless downpipe but are concerned about legal issues, consider the following:

- Tuning: Some tuning solutions can help in eliminating check engine lights (CEL) triggered by removing the catalytic converter.

- Using a Catted Option: Opting for a catted downpipe instead can provide a balance between performance and adherence to emissions standards.

- Track Use: If you plan to use your modified vehicle for racing or track events only, it may be permissible to use catless components.

Alternatives for Emission-Conscious Car Enthusiasts

For car enthusiasts who prioritize emissions but still want improved performance, there are alternatives to catless downpipes, such as:

- Catted Performance Downpipes: These downpipes include high-flow catalytic converters that maintain emissions compliance while boosting performance.

- Headers: Upgrading the vehicle’s headers can enhance exhaust flow and improve overall performance without compromising emissions.

- Exhaust System Upgrades: Complete exhaust system upgrades can work in tandem with downpipes to improve performance while meeting emissions standards.

Maintaining Your n55 Catless Downpipe

Regular Maintenance Tips for Longevity

To ensure the longevity and optimal performance of your n55 catless downpipe, consider the following maintenance tips:

- Monitor for rust or corrosion regularly, especially in areas with harsh weather conditions.

- Check for exhaust leaks periodically to maintain performance and avoid noise issues.

- Keep the exhaust system clean from dirt or debris that might cause blockages or damage.

Signs of Wear and Tear to Watch Out For

Being aware of signs that your n55 catless downpipe may need attention can prevent major issues down the line:

- Unusual noises from the exhaust can indicate a loose or damaged downpipe.

- Decreased performance or responsiveness could signal potential exhaust flow issues.

- Exhaust discoloration can suggest overheating or damage to the downpipe.

How to Clean and Care for Your Downpipe

Routine cleaning and care of your n55 catless downpipe can enhance its lifespan and performance:

- Use Non-Abrasive Cleaners: Regularly clean exposed areas with non-abrasive cleaning agents to prevent dirt buildup.

- Inspect Connections: Ensure all connections remain tight and free from debris or corrosion.

- Consider Heat Coating: Applying a heat-resistant ceramic coating can help protect against high temperatures and reduce the likelihood of corrosion.